Cost of Production Using a Valve Bag-Making Machine

The cost of production using a valve bag-making machine compared to other packaging methods can vary depending on several factors such as the type of product being packaged, the volume of production, and the specific requirements of the packaging process. However, there are some general considerations when comparing the cost of production using valve bag-making machines to other packaging methods:

1. Initial Investment

Valve bag-making machines typically require a significant initial investment compared to simpler packaging methods such as manual bagging or basic automated bagging systems. The cost of purchasing and installing a valve bag-making machine can be substantial, especially for smaller businesses or startups.

2. Labor Costs

Valve bag-making machines offer automation capabilities that can significantly reduce labor costs compared to manual packaging methods. While initial setup and maintenance require skilled personnel, once operational, these machines can streamline the packaging process and minimize the need for manual intervention.

3. Material Costs

Valve bags themselves may be slightly more expensive than traditional open-mouth bags or other packaging materials. However, the benefits of valve bags, such as improved product protection, reduced waste, and enhanced shelf life, can often justify the higher material costs.

4. Efficiency and Productivity

Valve bag-making machines are designed for high-speed, efficient production, allowing for increased throughput and productivity compared to manual or less automated packaging methods. This increased efficiency can result in lower overall production costs per unit packaged, especially for large-volume operations.

5. Maintenance and Operating Costs

While valve bag-making machines require regular maintenance to ensure optimal performance and longevity, the ongoing maintenance and operating costs are generally manageable compared to other packaging methods. Proper maintenance can help prevent downtime and costly repairs, ultimately contributing to lower production costs over time.

6. Customization and Flexibility

Valve bag-making machines offer flexibility in terms of bag size, material, and design, allowing businesses to customize their packaging to meet specific product requirements and consumer preferences. While this flexibility may entail additional setup or material costs, it can enhance product appeal and market competitiveness.

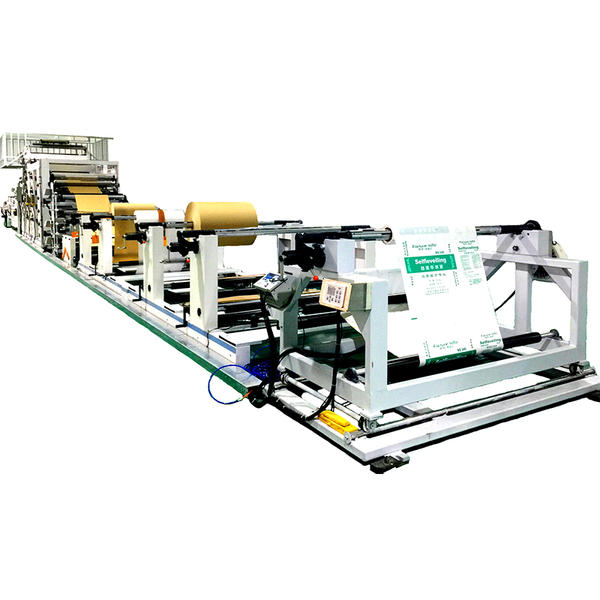

Tecon Basic Type Tube Machine

The machine is mainly used to make a bag, and a sewing bag or a valve pocket can be made based on the bag. The press is generally not equipped with a press unless the customer orders it separately. We often have a four-color printing machine with a scraper to ensure good print quality.

Operating Conditions

| Working time | 22 hours / day |

| Design working environment temperature | 0 ~ 40 °C |

| Design working environment humidity | up to 95% |

| Model | ZT 8762 |

The Technical Parameters

| Bag length | 700 ~ 970 mm |

| A-shaped edge tube width | 470 ~ 620 mm |

| Cutter | Step cut / straight cut |

| Number of layers | 4 paper + 1 film |

| Maximum production speed | 140 tubes / minute ( bag length:780 ~ 820 mm ) |

| Conventional stable production speed | 120 ~ 130 tubes / min |

| Maximum paper reel diameter | ∅1300 mm |

| Voltage and frequency | 380±10V 50H z |

| Equipment size | Without 4- color printing press: 30.5 x 2.8 x 2.7 m |

| With 4- color press | 34 x 2.8 x 2.7 m |

| Equipment weight | without 4- color printing machine: 25 tons |

| With 4- color printing machine | 31 tons |

| Total motor power | without 4- color printing machine: 24KW |

| With 4- color printing machine | 25.6KW |

Main Configuration (Basic Type)

| Ordinary paper reel racks | 5 (can produce 4 paper +1 film paper bags) |

| ZTC002 Layering mechanism | 1set |

| ZTD001 Rectification mechanism | 1 set 4 units |

| ZTE101 Auxiliary driving mechanism | 1 set |

| ZTE201 Horizontal perforation mechanism | 1 set |

| ZTE301 Horizontal glue dotting mechanism | 1 set |

| ZTE401 Longitudinal glue brushing mechanism | 1 set |

| ZTF001 Tube forming mechanism | 1 set |

| ZTG001 Main driving tearing off mechanism | 1 set |

| ZTH001 Counting, sorting out and outputting mechanism | 1 set |

| Electronic control system | 1 set |

Optional Configuration (Basic)

- Four-color printing machine with scraper ZTA006

- Intermittent puncture mechanism ZTE002

In summary, while the initial investment and material costs associated with valve bag-making machines may be higher compared to some other packaging methods, the long-term benefits in terms of labor savings, efficiency, and product quality often outweigh these initial expenses.

Do you want to know more about the features and benefits of a valve bag making machine? Contact us to explore how you can integrate our valve bag making machines into your packaging plans.