How to Choose the Right PP Cement Bag Making Machine?

In the realm of cement production, the importance of high-quality cement bags cannot be overstated.

These bags, typically made from polypropylene (PP), are vital for safeguarding and efficiently transporting cement.

Therefore, selecting the right PP cement bag making machine is a pivotal decision that can significantly impact your production process.

In this post, the author would guide you to select the right pp cement bag making machine.

These bags, typically made from polypropylene (PP), are vital for safeguarding and efficiently transporting cement.

Therefore, selecting the right PP cement bag making machine is a pivotal decision that can significantly impact your production process.

In this post, the author would guide you to select the right pp cement bag making machine.

What are PP Cement Bag Making Machines?

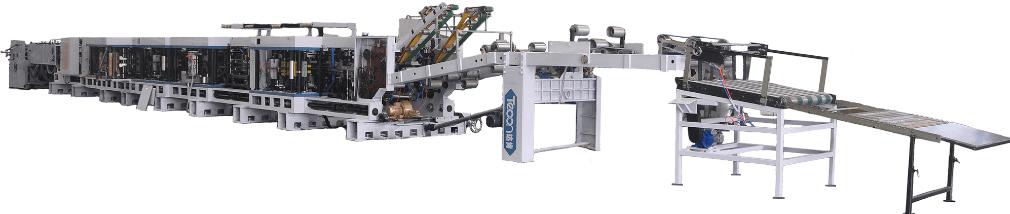

PP cement bag making machines are highly specialized devices designed to create cement bags from polypropylene material. These machines serve as the lifeblood of cement manufacturers and bag producers, streamlining the production of robust and custom-designed bags tailored to the exacting needs of the industry.

What are the Types of PP Cement Bag Making Machines?

PP cement bag making machines come in a diverse range of types, each with unique features and capabilities. Understanding these distinctions is essential for making an informed choice. Common types include:

Flat Belt Machines: Ideal for high-speed, continuous bag production.

Bottom-Stitch Machines: Well-suited for sealing the bottoms of bags securely.

Valve Bag Machines: Perfect for producing bags with built-in valve openings for filling.

By grasping the nuances of these machine types, you can make a decision that aligns perfectly with your production requirements.

Flat Belt Machines: Ideal for high-speed, continuous bag production.

Bottom-Stitch Machines: Well-suited for sealing the bottoms of bags securely.

Valve Bag Machines: Perfect for producing bags with built-in valve openings for filling.

By grasping the nuances of these machine types, you can make a decision that aligns perfectly with your production requirements.

Factors to Consider

After knowing the PP cement bag making machine, it is time for you to learn what factors you need to consider during the selection process.

Production Capacity

The production capacity of your chosen machine is the cornerstone of your decision. It should be in harmony with your business needs to guarantee a consistent supply of cement bags. To determine the appropriate capacity, consider your current demand and future growth projections, allowing for flexibility.

Bag Specifications

Cement bags arrive in various sizes, designs, and thicknesses. Your selected machine must be adaptable to accommodate specific bag specifications required for your product. Take into account factors such as bag size, design options, and the machine's capability to produce multi-layer bags if needed.

Material Compatibility

Polypropylene is the material of choice for cement bags, renowned for its robustness and durability. It is vital that your chosen machine is impeccably compatible with polypropylene to ensure the production of high-quality, reliable bags.

Automation and Features

The level of automation and features offered by different machines can be a game-changer in terms of efficiency and cost savings. These features might include:

Printing Options: For branding and labeling bags efficiently.

Bag Counting Mechanisms: To maintain control over the production process.

Ease of Setup and Operation: Simplifying the learning curve for your team.

By assessing your specific needs in terms of automation, you can maximize the efficiency of your production line.

Printing Options: For branding and labeling bags efficiently.

Bag Counting Mechanisms: To maintain control over the production process.

Ease of Setup and Operation: Simplifying the learning curve for your team.

By assessing your specific needs in terms of automation, you can maximize the efficiency of your production line.

Durability and Maintenance

In the manufacturing environment, durability is non-negotiable. Look for machines constructed from high-quality materials and endorsed by reputable manufacturers. Consider the maintenance requirements and schedules to ensure a prolonged and trouble-free service life for your machine.

Cost and Budget

While budget constraints are always a consideration, remember that investing in a more reliable machine can often pay dividends in the long run by reducing downtime and maintenance expenses. Striking the right balance between cost-effectiveness and quality is crucial.

Researching and Comparing Machines

Researching and Comparing Machines

Market Research

Extensive market research is the cornerstone of making an informed decision. Explore online resources, industry publications, and attend trade shows to gather information on the array of available options. This will provide you with a well-rounded perspective of the marketplace.

Requesting Quotes and Proposals

To narrow down your options, initiate contact with machine manufacturers and request comprehensive quotes and proposals. These documents should offer a detailed overview of the machine's specifications, pricing, and delivery times, enabling a direct comparison.

Comparing Options

Creating a comparison matrix or chart can be a powerful tool for assessing the pros and cons of different machines. Consider variables such as upfront cost, production capacity, included features, and material compatibility. A well-organized comparison can be instrumental in your decision-making process.

Evaluating Manufacturers and Suppliers

Prioritize manufacturers with solid reputations and extensive experience in the field. Established companies often deliver higher-quality machines and superior customer support. Their wealth of experience can prove invaluable in guiding your decision.

Customer Reviews and References

Customer feedback can be a goldmine of insights. Peruse customer reviews and actively seek references from others who have procured similar machines. Feedback from previous customers is a reliable gauge of a machine's performance and the manufacturer's commitment to customer satisfaction.

Making the Final Decision

Before finalizing your decision, recapitulate and reflect on all the factors discussed above. Verify that the selected machine aligns with your production requirements, budget, and bag specifications, ensuring that it's a perfect fit for your business.

Finalizing the Budget

If necessary, adjust your budget based on the information and quotes you've gathered. A clear and well-defined budget will guide your decision-making process and prevent costly overspending.

Contacting Manufacturers

Communicate effectively with the shortlisted manufacturers, addressing any remaining questions and concerns. This personal interaction can provide clarity and confidence in your final choice.

Warranty and Support

Thoroughly review the terms and conditions of the manufacturer's warranty and post-purchase support. A robust warranty not only instills confidence but also ensures that you have a safety net in case unexpected issues arise.

Conclusion

Selecting the right PP cement bag making machine is a decision that profoundly impacts your cement production and packaging.

By taking into account factors such as production capacity, bag specifications, material compatibility, features, durability, and budget constraints, and conducting meticulous research, you can make a choice that not only meets your current needs but positions your business for success in the future.

Remember, an informed decision today translates to efficient and cost-effective cement bag production in the years to come, enhancing your competitiveness and reputation in the industry.

By taking into account factors such as production capacity, bag specifications, material compatibility, features, durability, and budget constraints, and conducting meticulous research, you can make a choice that not only meets your current needs but positions your business for success in the future.

Remember, an informed decision today translates to efficient and cost-effective cement bag production in the years to come, enhancing your competitiveness and reputation in the industry.