Why Valve Bag Making Machine Speed Matters for Large-Scale Production?

In large-scale industrial packaging, efficiency is everything. The speed of a valve bag making machine directly impacts production capacity, cost-effectiveness, and overall profitability. For manufacturers producing thousands of valve bags daily, machine speed is not just a convenience—it’s a necessity.

A high-speed valve bag making machine ensures that manufacturers meet growing demand, reduce downtime, and improve operational efficiency. But how exactly does speed influence large-scale production? And what should buyers consider when investing in a machine built for high-performance packaging?

The Impact of Machine Speed on Production Efficiency

The faster a valve bag making machine operates, the greater the output per shift. In industries like cement, chemical, and food packaging, where demand fluctuates, a high-speed machine ensures that businesses can scale production without requiring excessive labor or additional machines.

1. Meeting High Demand with Faster Production

For bulk product manufacturers, speed is crucial. A slow machine limits daily output, creating bottlenecks in the supply chain. High-speed valve bag making machines allow businesses to stay competitive by handling large orders efficiently.

2. Reducing Labor and Operational Costs

A high-speed machine minimizes the need for manual intervention, reducing labor costs. Fewer workers are needed to oversee production, and with automation, the risk of human error is significantly lower. This leads to higher consistency and quality control.

3. Maximizing Machine Utilization and ROI

Investing in a fast and reliable valve bag making machine ensures better machine utilization. When a machine can produce more bags per hour, manufacturers maximize their return on investment (ROI) faster by reducing operational overhead and increasing profit margins.

Key Factors Affecting Valve Bag Making Machine Speed

Several factors influence the speed and efficiency of a valve bag making machine. Understanding these elements helps buyers select the right equipment for their needs.

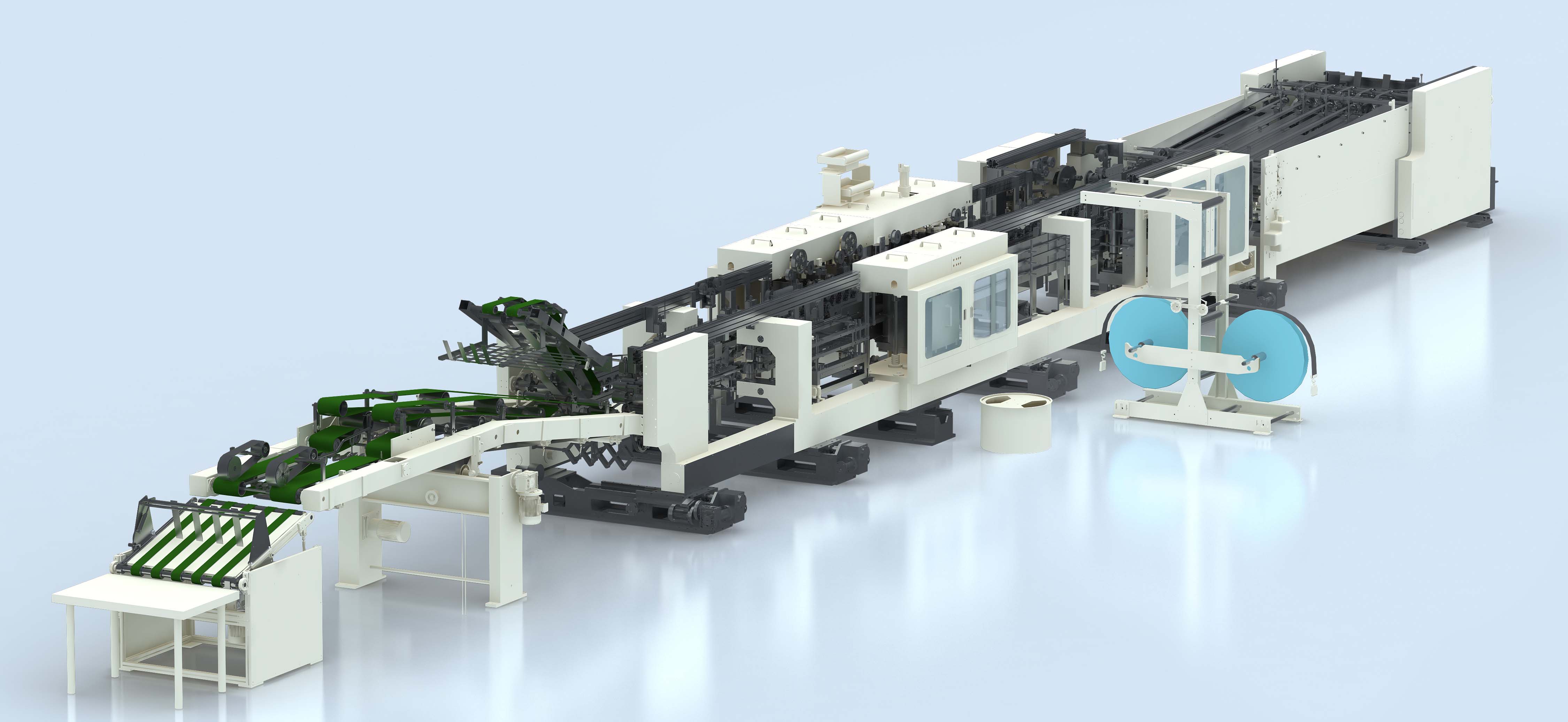

1. Advanced Automation and Control Systems

Modern machines integrate PLC control systems, servo motors, and touch-screen interfaces, allowing precise adjustments to speed settings. Automation reduces machine downtime and ensures continuous high-speed operation without frequent manual adjustments.

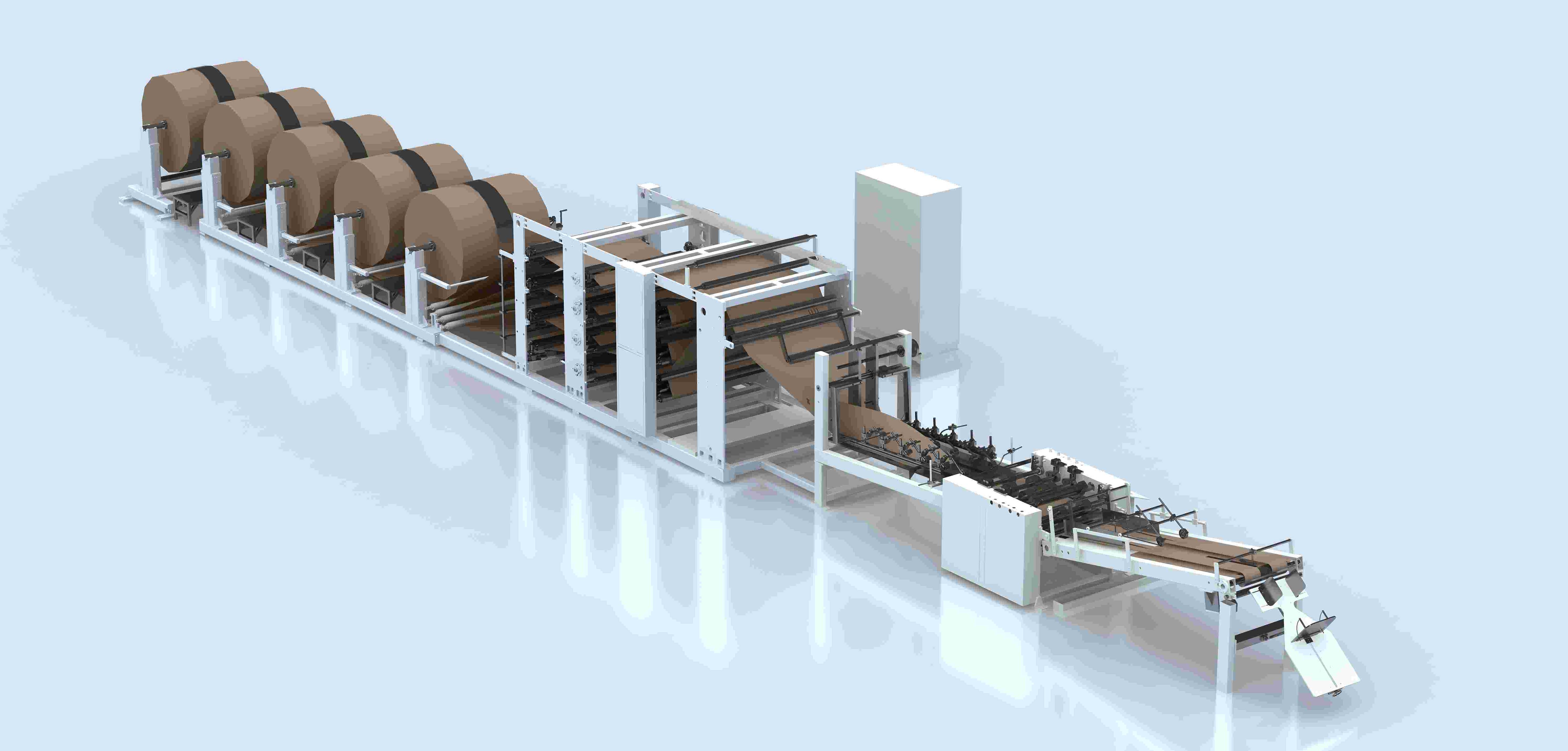

2. Material Compatibility and Seamless Processing

The type of materials used in valve bag production, such as polyethylene (PE), polypropylene (PP), and paper, affects machine speed. A machine designed for multiple material types offers flexibility while maintaining high-speed output without sacrificing bag quality.

3. Cutting and Sealing Technology

Fast cutting and sealing mechanisms improve production speed without compromising bag durability. High-quality heat sealing and ultrasonic sealing technologies ensure strong seams, preventing leakage and enhancing bag performance in various industries.

4. Efficient Reel Unwinding and Folding Mechanisms

High-speed machines use automatic tension control and precise alignment systems to ensure smooth reel unwinding, folding, and valve application. This prevents material jams and reduces machine stoppages, ensuring uninterrupted high-speed production.

Choosing the Right High-Speed Valve Bag Making Machine

When selecting a valve bag making machine, buyers should consider:

● Production Capacity: Choose a machine that aligns with current and future demand.

● Automation Level: Fully automated machines offer higher efficiency and precision.

● Energy Efficiency: Faster machines should also optimize energy consumption.

● Customization Options: Ensure the machine can handle various bag sizes and materials for flexibility.

Conclusion

Speed is a critical factor when investing in a valve bag making machine for large-scale production. A high-speed machine increases output, reduces costs, and enhances efficiency—key elements for any manufacturer looking to stay competitive.

For businesses seeking customized valve bag making solutions, selecting the right machine ensures long-term productivity and profitability. By focusing on speed, automation, and material compatibility, you can streamline your packaging operations and scale production effortlessly.

Tecon Tuber Machine

Tecon Tuber Machine